Your Playbook for Procuring Injection Molding Services from China

So, the big meeting just wrapped up. your new project has the green light, time is pressing, and the budget is… well, let’s just say it’s tight.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

You nod, of course. It makes sense on paper. The potential savings can be massive. However, your brain is racing with concerns. You know the rumors, don’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

Here’s the thing, though. Procuring plastic mold needn’t be a roll of the dice. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Ignore the nightmare anecdotes. Let’s go through a step-by-step guide to succeed.

First Things First: Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

So, what goes in it?

First, your 3D CAD files. They’re essential. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the authoritative CAD geometry.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. This details critical info missing from the 3D file. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Any seal surfaces or critical hole sizes must be clearly labeled.

Next up, material. Don’t label it simply “Plastic.” Even “ABS” alone is too vague. Be specific. Call out SABIC Cycolac MG38 (black), for example. Why be exact? Because there are thousands of plastic variations. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Lastly, add your business data. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? Tool style, cavity count, and unit cost are volume-driven.

The Great Supplier Hunt

Okay, your RFQ package is a work of art. who will you target? The web is vast but overwhelming. It’s easy to find a supplier; it’s hard to find a good one.

Your search will likely start on platforms like Alibaba or Made-in-China.com. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. Narrow your pool to about a dozen promising firms.

But don’t stop there. Think about engaging a sourcing agent. They do cost extra. Yet top agents deliver reliable, audited suppliers. They handle local liaison and oversight. As a newcomer, this offers priceless security. It’s schedule protection.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Nothing beats a face-to-face conversation. Inspect prototypes, interview engineers, and sense their capabilities. Plus, ask peers for referrals. Consult trusted colleagues. A recommendation from a trusted peer is often worth its weight in gold.

Shortlisting Serious Suppliers

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. the quotes will start trickling in. You’ll see ridiculously low offers and steep quotes. Your task is to filter them down to 2–3 credible finalists.

How to proceed? It blends technical checks with intuition.

Begin with responsiveness. Are their replies prompt and clear? Can they handle detailed English exchanges? But here’s the real test: Are they asking you intelligent questions? A great supplier will review your RFQ and come back with thoughts. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” This is a massive green flag. It shows they’re engaged and experienced. Anyone who simply agrees to all specs is a red flag.

Afterward, verify their technical arsenal. Ask for a list of their equipment. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Next up: the factory audit. Skipping this is a mistake. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They’ll send a local inspector to the factory for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s the best few hundred dollars you will ever spend on your project.

From Digital File to Physical Part

Once you’ve chosen your supplier. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Then comes the real action.

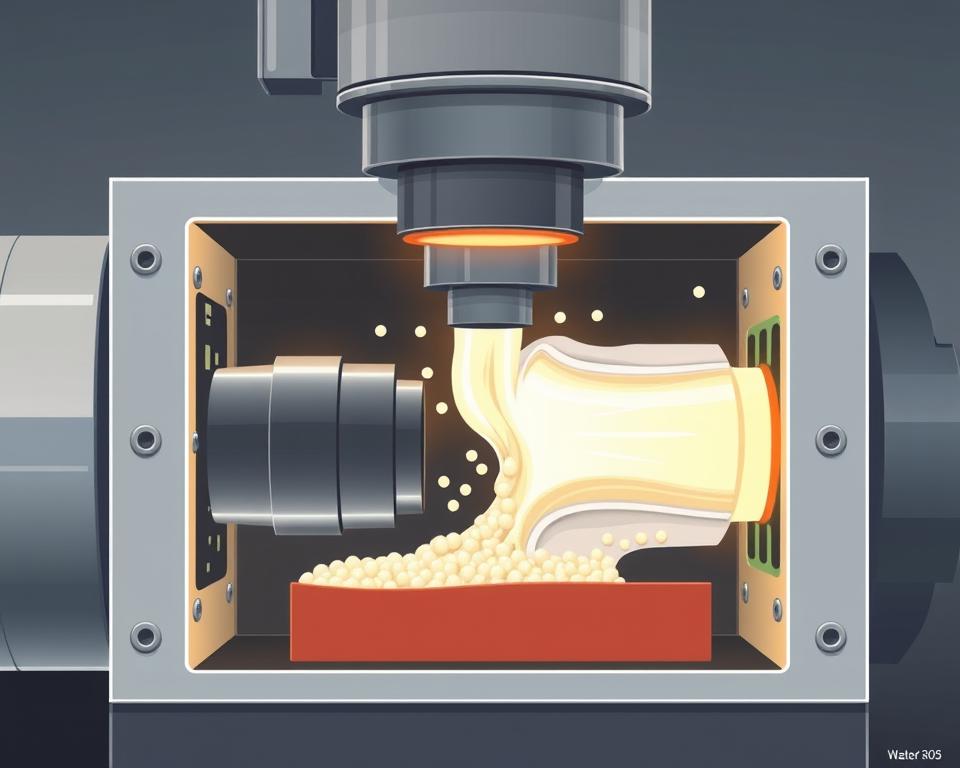

The first thing you should get back after sending your payment is a DFM report. Design for Manufacturability (DFM) is essential. It’s their professional review of your CAD. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. Comprehensive DFM equals a top-tier supplier. It becomes a joint effort. Together, you tweak the design for best manufacturability.

When you greenlight the DFM, they machine the mold. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. They are your moment of truth.

T1 parts usually require adjustments. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. You may repeat this cycle a few times. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

Eventually, you will receive a part that is perfect. Dimensions, finish, and performance all check out. This is now the benchmark sample. You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Next up: mass manufacturing. How do you ensure that the 10,000th part is just as good as the golden sample?

Put a strong QC process in place. This often involves a pre-shipment inspection. Use a third-party inspector again. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They provide a photo-filled inspection report. After your approval, you release the shipment and final funds. This simple step prevents you from receiving a container full of scrap metal.

Don’t forget shipping details. Know your shipping terms. Does FOB apply, passing risk at the ship’s rail? Or EXW, shifting all transport to you? These details have a big impact on your final landed cost.

China sourcing is a long-haul effort. It relies on partnership-building. View them as allies, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.